Tianjin Yamaha Electronic Musical Instrument Co., Ltd. is the first Sino-foreign joint venture subsidiary invested by Yamaha Corporation of Japan in China. The Tianjin Yamaha assembly workshop has six production lines, which also produce different models of electronic pianos, electric pianos and synthesizers under the company. The company’s annual output is maintained at over 1.1 million units, with an annual sales revenue of over RMB 1 billion.

Project Background

Tianjin Yamaha Electronic Musical Instrument Co., Ltd. has a low efficiency of the air conditioning system pumps in the refrigeration machine room and lacks an intelligent group control system, relying solely on the manual operation of staff to achieve the start and stop of the system.

Solutions

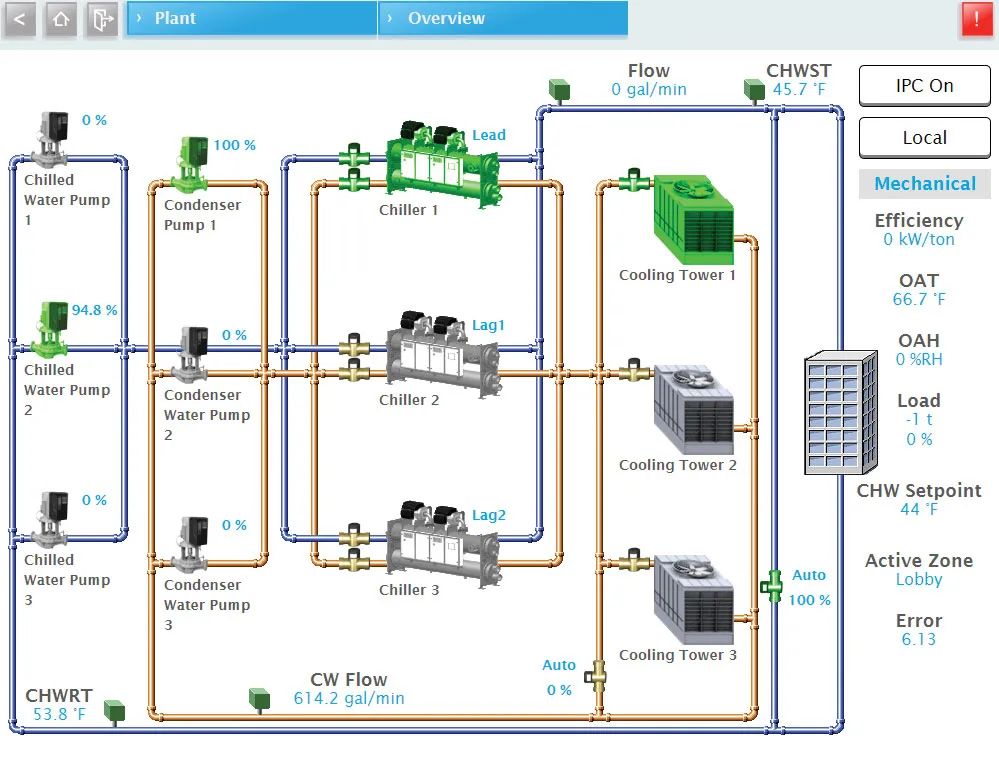

The technical team of Hengtong optimised the design of the workshop room system in response to the above situation: the original energy-inefficient chilled and cooling water pumps were replaced with ARMSTRONG intelligent inverter pumps, while the intelligent control system was adopted to centralise energy-saving control, monitoring and operating status analysis of energy-consuming equipment such as pumps, chillers and cooling towers. The remote transmission function of the equipment was added, so that the operating status of the system can be viewed through computers and mobile phone applets, while the Huntoon Cloud Data Centre is manned by a dedicated person who can monitor and analyse and diagnose the status of the units 24 hours a day.

The project has an installed capacity of 1255*3=3765kW, with matching replacement refrigeration and cooling pumping units.

Data comparison

Annual electricity savings638838KWh

Annual electricity consumption before conversion 1486485kwh

Annual electricity consumption after renovation 847,647kwh

Annual electricity saving rate42.98 %

Benefit analysis

Economic benefits

The refrigeration and air-conditioning system can save 638,000 kwh of electricity throughout the year, which translates into a reduction in operating costs of 478,000 yuan (a comprehensive electricity price of 0.75 yuan/kW*h) and an average annual electricity saving rate of 43%.

Environmental benefits

It saves 200 tonnes of standard coal and reduces CO2 emissions by 498 tonnes per year.

Maintenance benefits

All data of the system is transmitted wirelessly to the cloud, so that the real-time status of the equipment and the history of individual parameters can be grasped in time. Other intelligent terminal devices such as mobile phones can also be used for all-round commissioning, operation, monitoring and energy efficiency management services of all equipment. The Henton cloud data platform monitors the operation status of the system in real time and has dedicated personnel to monitor it 24 hours a day.

Management benefits

Fully automatic energy saving control, reduced operational risk, labour intensity and management costs, less manning and improved system safety.