SEW-Industrial Reducers (Tianjin) Co., Ltd. is a large, wholly-owned manufacturing plant of SEW in the Tianjin Economic and Technological Development Area. With a total investment of 300 million Euros and an area of 175,000 square metres, it has the most modern plant, manufacturing processing and testing equipment, and is one of the 12 largest manufacturing plants of the SEW Group worldwide and the manufacturing centre of SEW in the Asia-Pacific region.

Original problems with the machine room

1.The original equipment layout and piping selection was unreasonable and needed to be re-arranged.

2.The pressure of the make-up device is low and the water needs to be made up manually, so it is necessary to add a constant pressure make-up device.

3.Insufficient space in the original distribution cabinet, which needs to be re-sorted to match the frequency-controlled chilled cooling pumps

4.The system equipment lacks an integrated control system and is designed to incorporate efficient machine room control points and individual sensors and function points.

Integrated high efficiency plant room – construction process

In order to save installation time on site, to improve the quality and efficiency of the system, and to make the connection between the various processes more compact, the system was assembled in a prefabricated manner.

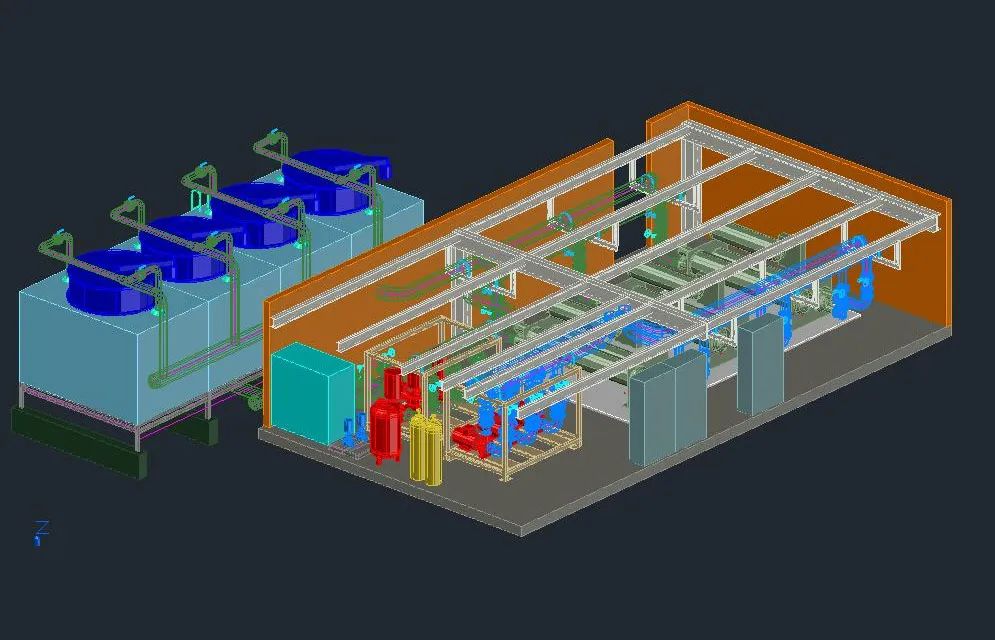

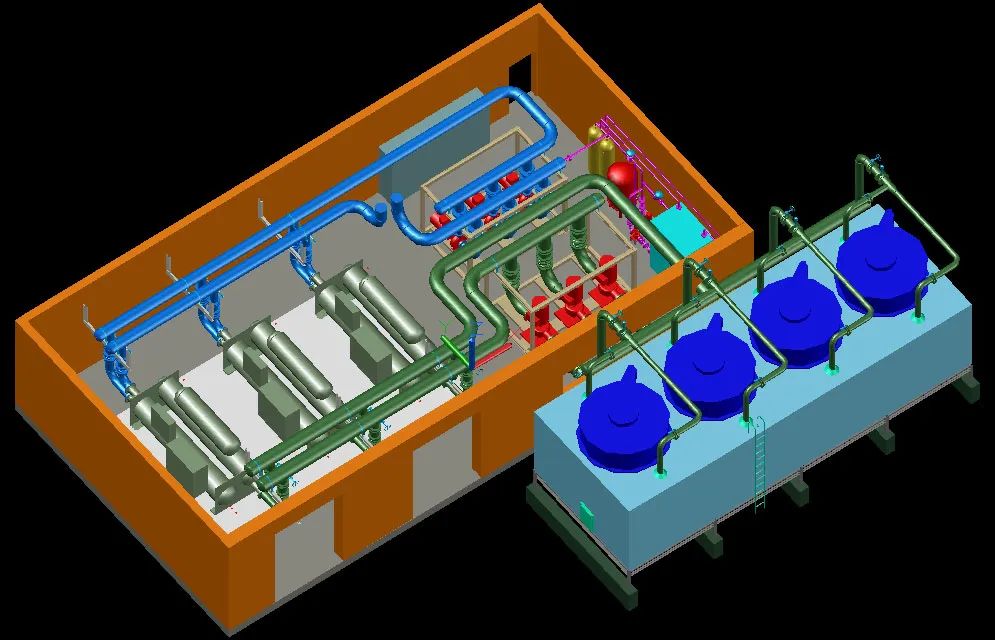

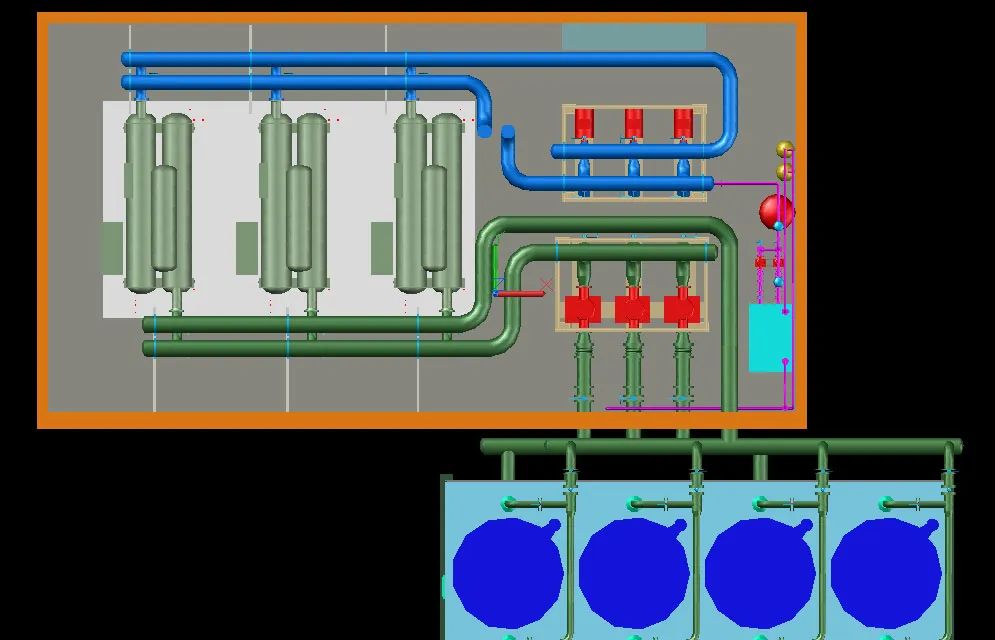

Three-dimensional simulation, integrated layout

Henton BIM engineers fully planned and utilised the site installation location for the system design based on the dimensions of the site installation location in conjunction with the updated equipment dimensions.

The layout is optimised according to the site’s original foundation location and the location of the mains inlet and outlet, making the system less resistant and the plant room more tidy and beautiful. Compared to the original layout of the plant room, 12 elbows and 17 metres of piping have been reduced.

Equipment prefabrication, module production

According to the BIM model accurate material, prefabricated piping model in Huntoon workshop, the equipment and piping assembly will be completed and delivered to the site in the form of a whole refrigeration plant room, landing to connect the piping and electrical parts can, both save the time of site construction, but also can be completed in advance, fully save the construction period.

The prefabricated workshop is mainly equipped with automatic welding machines, cutting machines, pipe storage brackets, semi-finished product stacking areas and sanding machines.

According to the BIM model accurate material, prefabricated piping model in Huntoon workshop, the equipment and piping assembly will be completed and delivered to the site in the form of a whole refrigeration plant room, landing to connect the piping and electrical parts can, both save the time of site construction, but also can be completed in advance, fully save the construction period.

Logistics and transport

According to the size of the assembly module, comprehensive consideration of the vehicle space to maximize the efficiency of the use of shipment; before the delivery of finished products to do a good job of protection, the use of stretch film, straw rope on the members of the collision-prone position for packaging, loading.

After conversion

Advantages of an efficient integrated server room

Factory pre-assembled system solutions, with energy-efficient control systems as the core, integrate all related equipment into one model, apply the idea of integral structure design, apply integrated wiring technology, computer network technology, integrate all equipment, functions and information into an interrelated, unified and coordinated system, withFast installation, small footprint, easy maintenance, energy efficientThe advantages of the product include Widely used in commercial and industrial cooling water cooling systems.

Energy efficient

Annual COP of 5.0, 40% more energy efficient than traditional server rooms

Easy installation

3D simulation, factory prefabrication, modular installation, saving time

Small footprint

Reasonable layout, fully saving floor space, 30% less than traditional server room

Easy maintenance

Intelligent control and monitoring of equipment operation at all times

Assembly Star

SEW Tianjin Plant F2 Refrigeration Room Upgrade Project” by Tianjin Hengtong at the award ceremony of the 2nd National Assembly Mechanical and Electrical Engineering Design and Application Skills CompetitionRefrigeration system design andBIMApplicationsAwarded the title of Assembly Star in the Design Group.